Description

TRADITIONAL REACTIVE ACID STAIN

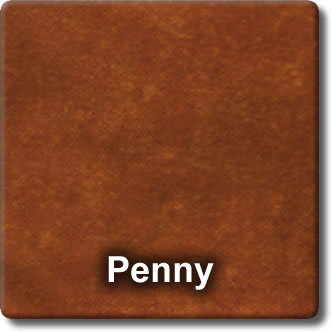

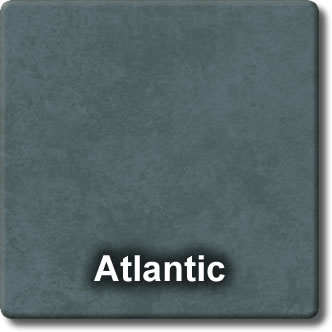

Beautifully and permanently color concrete in 9 rich earth tone colors. Acid stains chemically react with the mineral content and excess lime of the concrete surface for a deep penetrating permanent stain. The beautiful natural colors created by Surfkoat's Heritage Acid Stains are unique to each piece of concrete and have a mottled antique patina.

Because of their superior UV stability, acid stains are always a good choice for for outdoor projects like driveways, sidewalks, pool decks and patios. If properly sealed and maintained, the color of acid stained concrete is permanent and will last as long as the concrete itself. Acid stains can only be used on clean, bare and un-sealed concrete surfaces.

Surfkoat Acid Stains can also be used on other outdoor surfaces such as, Concrete Block, Natural Stone and Manufactured Stone. Of course you should always test for compatibility and desired results when using as a stain for concrete or cinder block or a stain for stone. Acid stains should always be sealed after application to protect the colored surface.

Heritage Acid Stain is available in 9 earth-tone colors:

Not sure which color is right for you?

Our 4 oz Acid Stain sample sizes make it easy to choose!

Essentials

- For bare, unsealed concrete only

- Concrete must be cured +28 days

- Permanent color

- Must be sealed to protect color

- Spray Application

- Coverage - See Detailed Info

![]() Warning: This product can expose you to chemicals including Chromium, which is known to the State of California to cause cancer and known to the State of California to cause birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov.

Warning: This product can expose you to chemicals including Chromium, which is known to the State of California to cause cancer and known to the State of California to cause birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov.

Detailed Info!

To learn more, keep reading or click a link below to jump to a specific topic:

- Detailed Description

- Cleaning and Preparation Instructions

- Application Instructions

- Sealing

- Maintenance

- FAQ's

Heritage Acid Stain

For outdoor projects, acid stains are still a great option and actually preferred because of their superior UV stability. The messy rinsing, neutralizing and scrubbing is also much easier outdoors. Acid stains are always a good choice for outdoor projects like driveways, sidewalks, pool decks and patios. If properly sealed and maintained, the color of acid stained concrete is permanent and will last as long as the concrete itself. Acid stains can only be used on clean, bare and un-sealed concrete surfaces.

Surfkoat Acid Stains can also be used to color other outdoor surfaces such as, Concrete Block, Natural Stone and Manufactured Stone. When using acid stain for staining concrete, for staining block or for staining stone, always perform a test spot to ensure the color and results are desirable. Remember, acid stains take time to work and must be neutralized to develop the true color. The choice of sealer you use will also influence the final result. Acid stains should always be sealed after application to protect the colored surface.

Greens and Blues are for interior use only. If exposed to UV light they can turn black over time.

Cleaning and Preparation Instructions

2. Use only the amount of cleaners necessary to remove contaminates, oils, fluids and sealers from the substrate. Rinse thoroughly! Surface and pores must be clean and free of all chemicals before applying Acid Stain.

4. Allow area to dry completely.

Application Instructions

Before application, always test the stain in an inconspicuous area to ensure color and compatibility are acceptable. Allow to dry for 4-6 hours. Neutralize and rinse the test area, observing the color while wet. This will approximate the sealed color (if using a color enhancing sealer). Concrete should be fully cured for 28 days before acid staining.

Perform moisture vapor test by taping a plastic sheet on a one square foot section of floor. Remove plastic the following day. If floor is wet, DO NOT PROCEED. First determine if moisture is remaining from the cleaning process, or if it is a more serious issue coming from the soil below the slab. If you suspect a moisture issue from beneath the slab, DO NOT PROCEED.

Protect all areas not to be stained. Mask off all adjacent surfaces. Use coated cardboard as a spray shield. Do not use metal tools or sprayer. Before opening or handling acid stain, first put on proper protective equipment including eye protection, rubber gloves and acid resistant respirator.

Surfkoat Concentrated Acid Stains may be diluted up to 1:1 with water to create lighter colors if desired.

Multiple colors of Acid Stain may be used to create any desired combination of colors, highlights and contrast. If using multiple colors, always start with the lightest color first as a base coat.

Remove residue and pour water on floor to approximate the final color. If darker color is desired, apply second coat. Allow second coat to react for at least 6 hours.

Coverage Rates: Coverage rates are approximate and will vary depending on substrate density, porosity and temperature. In most cases, two coats are desired to create a deep rich color. Coverage rates based on total combined two coat application.

Broom swept concrete: 200-250 sq. ft. / gallon

Troweled concrete: 200-250 sq. ft. / gallon

Sealing

After acid stained surface has dried for a MINIMUM of 24 hours. Again, perform a moisture vapor test by taping a plastic sheet on one square foot of floor. Remove plastic the following day. If floor is wet, DO NOT PROCEED. Allow floor additional time to dry from the staining process. In winter months or in basements, this could take anywhere from 24 hours to a month or more. Whatever you do, don't take a chance on trapping moisture in the slab. Moisture trapped below a sealer or coating will cause the sealer to blister, peel or turn white, resulting in a costly disaster for you. When moisture testing confirms the slab is dry, you are now ready to seal the concrete.

You have many choices when it comes to choosing a sealer. Several factors including budget, durability and desired appearance will influence this decision. To give you a starting point, here are our most popular recommendations:

Interior Floors - High Performance:

First Coat (primer coat):

Polyrez 6000 WB Urethane (for enhanced color)

Polyrez 1040 WB Epoxy (for minimal enhancement)

Second Coat (topcoat):

Polyrez 6000 WB Urethane (for a gloss finish)

Polyrez 6100 WB Matte Urethane (for a matte finish)

Interior Floors - Economical:

Outdoor Concrete - Film-Forming Sealers:

Deco-Guard, StampSeal-25, 2000 Supreme, or Hurricane CAT-5

Outdoor Concrete, Block & Stone - Penetrating Sealers:

Enhancer Shield, SB-100, or WB-75

Be sure to choose the appropriate sealer for your application. If you need help, check out the "Help Center" or just give us a call and we'll be glad to walk through the process with you. That's what we're here for!

Of course, having the right tools will make your job easier, so scroll to the bottom to see our recommended Sprayers, Brushes and Application Tools!

Maintenance

Maintain protective top-coat or sealer according to manufacturers recommendations.

FAQ's

Got Questions?

Check out the "Help Center", send us an email or just give us a call and we'll be glad to help you with your order!