-

$194.00Size: 5 Gallon

$194.00Size: 5 Gallon -

SEK / Trident

Trident Hurricane CAT 5

$319.35 - $675.37Water-based products may experience shipping delays during cold weather months! If freezing temps are forecast, we will hold your order until safe to ship. We monitor forecast conditions everyday and will ship your order as soon as safely possible. -

$7.00 - $128.94Water-based products may experience shipping delays during cold weather months! If freezing temps are forecast, we will hold your order until safe to ship. We monitor forecast conditions everyday and will ship your order as soon as safely possible.

$7.00 - $128.94Water-based products may experience shipping delays during cold weather months! If freezing temps are forecast, we will hold your order until safe to ship. We monitor forecast conditions everyday and will ship your order as soon as safely possible. -

$7.00 - $232.17Due to flammability Low VOC versions of this product must ship with a special DOT classification and cannot be returned.

$7.00 - $232.17Due to flammability Low VOC versions of this product must ship with a special DOT classification and cannot be returned. -

Surfkoat

Stamp-Seal Pure Acrylic

$7.00 - $223.72Due to flammability Low VOC versions of this product must ship with a special DOT classification and cannot be returned. -

Surfkoat

Deco-Guard Siloxane-Acrylic

$7.00 - $276.16Low VOC Solvent-Based versions of this product must ship with a special DOT classification and cannot be returned. - The Water-Based version may experience shipping delays during cold weather months. -

$7.00 - $320.00The Solvent-Based version of this product must ship with a special DOT classification and cannot be returned. - The Water-Based version may experience shipping delays during cold weather months.

$7.00 - $320.00The Solvent-Based version of this product must ship with a special DOT classification and cannot be returned. - The Water-Based version may experience shipping delays during cold weather months. -

$7.00 - $440.72

$7.00 - $440.72 -

$7.00 - $58.05

$7.00 - $58.05 -

$7.00 - $50.90This product must ship with a special DOT classification and cannot be returned.

$7.00 - $50.90This product must ship with a special DOT classification and cannot be returned. -

$7.00 - $274.21Due to flammability Low VOC versions of this product must ship with a special DOT classification and cannot be returned.

$7.00 - $274.21Due to flammability Low VOC versions of this product must ship with a special DOT classification and cannot be returned. -

$7.00 - $66.33Due to flammability this product must ship with a special DOT classification and cannot be returned.

$7.00 - $66.33Due to flammability this product must ship with a special DOT classification and cannot be returned. -

$155.88 - $265.31Water-based products may experience shipping delays during cold weather months! If freezing temps are forecast, we will hold your order until safe to ship. We monitor forecast conditions everyday and will ship your order as soon as safely possible.

$155.88 - $265.31Water-based products may experience shipping delays during cold weather months! If freezing temps are forecast, we will hold your order until safe to ship. We monitor forecast conditions everyday and will ship your order as soon as safely possible. -

$196.03 - $359.06Water-based products may experience shipping delays during cold weather months! If freezing temps are forecast, we will hold your order until safe to ship. We monitor forecast conditions everyday and will ship your order as soon as safely possible.

$196.03 - $359.06Water-based products may experience shipping delays during cold weather months! If freezing temps are forecast, we will hold your order until safe to ship. We monitor forecast conditions everyday and will ship your order as soon as safely possible. -

$284.44 - $1,369.91

$284.44 - $1,369.91 -

Surfkoat

Polyrez 1040 Water-Based Epoxy

$188.56 - $848.83Water-based products may experience shipping delays during cold weather months! If freezing temps are forecast, we will hold your order until safe to ship. We monitor forecast conditions everyday and will ship your order as soon as safely possible. -

$226.03 - $1,115.75This product must ship with a special DOT classification and cannot be returned.

$226.03 - $1,115.75This product must ship with a special DOT classification and cannot be returned. -

Surfkoat

Polyrez 250 HP 100% Solids Epoxy

$216.15 - $1,131.95This product must ship with a special DOT classification and cannot be returned. -

$34.66 - $166.76

$34.66 - $166.76 -

$7.00 - $36.30

$7.00 - $36.30 -

$190.52 - $204.95Size: 40 Pound Box

$190.52 - $204.95Size: 40 Pound Box -

Surfkoat

Polyrez Epoxy Accelerator

$17.64Size: Premeasured for 3 gallon epoxy kit -

Surfkoat

Penetrating and Mottling Additive

$25.46Size: 20 oz bottle -

$13.75 - $445.50

$13.75 - $445.50 -

Surfkoat

Rapid Set Crack Repair System

$100.98 - $186.98 -

Surfkoat

Matte-50 Matte Finish Additive

$22.67Due to flammability this product must ship with a special DOT classification and cannot be returned. -

$44.00Water-based products may experience shipping delays during cold weather months! If freezing temps are forecast, we will hold your order until safe to ship. We monitor forecast conditions everyday and will ship your order as soon as safely possible.

$44.00Water-based products may experience shipping delays during cold weather months! If freezing temps are forecast, we will hold your order until safe to ship. We monitor forecast conditions everyday and will ship your order as soon as safely possible. -

$7.00 - $62.75Due to flammability this product must ship with a special DOT classification and cannot be returned.

$7.00 - $62.75Due to flammability this product must ship with a special DOT classification and cannot be returned. -

$39.87Size: Premeasured to tint 3 gallons of epoxy

$39.87Size: Premeasured to tint 3 gallons of epoxy -

$63.84Due to flammability this product must ship with a special DOT classification and cannot be returned.

$63.84Due to flammability this product must ship with a special DOT classification and cannot be returned. -

$40.96 - $155.55Water-based products may experience shipping delays during cold weather months! If freezing temps are forecast, we will hold your order until safe to ship. We monitor forecast conditions everyday and will ship your order as soon as safely possible.

$40.96 - $155.55Water-based products may experience shipping delays during cold weather months! If freezing temps are forecast, we will hold your order until safe to ship. We monitor forecast conditions everyday and will ship your order as soon as safely possible. -

Surfkoat

Repel-Cure Reactive Cure & Seal

$90.41 - $208.20This product must ship with a special DOT classification and cannot be returned. -

Surfkoat

2500 LV-UV Cure & Seal

$37.74 - $214.49Due to flammability Low VOC versions of this product must ship with a special DOT classification and cannot be returned. -

$7.00 - $57.87Water-based products may experience shipping delays during cold weather months! If freezing temps are forecast, we will hold your order until safe to ship. We monitor forecast conditions everyday and will ship your order as soon as safely possible.

$7.00 - $57.87Water-based products may experience shipping delays during cold weather months! If freezing temps are forecast, we will hold your order until safe to ship. We monitor forecast conditions everyday and will ship your order as soon as safely possible. -

$7.00 - $291.41Water-based products may experience shipping delays during cold weather months! If freezing temps are forecast, we will hold your order until safe to ship. We monitor forecast conditions everyday and will ship your order as soon as safely possible.

$7.00 - $291.41Water-based products may experience shipping delays during cold weather months! If freezing temps are forecast, we will hold your order until safe to ship. We monitor forecast conditions everyday and will ship your order as soon as safely possible. -

$56.00This product must ship with a special DOT classification and cannot be returned.

$56.00This product must ship with a special DOT classification and cannot be returned. -

$49.00Water-based products may experience shipping delays during cold weather months! If freezing temps are forecast, we will hold your order until safe to ship. We monitor forecast conditions everyday and will ship your order as soon as safely possible.

$49.00Water-based products may experience shipping delays during cold weather months! If freezing temps are forecast, we will hold your order until safe to ship. We monitor forecast conditions everyday and will ship your order as soon as safely possible. -

$56.00This product must ship with a special DOT classification and cannot be returned.

$56.00This product must ship with a special DOT classification and cannot be returned. -

$56.00This product must ship with a special DOT classification and cannot be returned.

$56.00This product must ship with a special DOT classification and cannot be returned. -

$7.00 - $157.75Water-based products may experience shipping delays during cold weather months! If freezing temps are forecast, we will hold your order until safe to ship. We monitor forecast conditions everyday and will ship your order as soon as safely possible.

$7.00 - $157.75Water-based products may experience shipping delays during cold weather months! If freezing temps are forecast, we will hold your order until safe to ship. We monitor forecast conditions everyday and will ship your order as soon as safely possible. -

Surfkoat

Nock-Off Sealer and Coating Stripper

$7.00 - $293.98 -

Surfkoat

Surf-Prep Concrete Etching Cleaner

$7.00 - $220.30This product must ship with a special DOT classification and cannot be returned. -

Surfkoat

Balance Neutralizer and Enhancer

$19.16 - $51.89Water-based products may experience shipping delays during cold weather months! If freezing temps are forecast, we will hold your order until safe to ship. We monitor forecast conditions everyday and will ship your order as soon as safely possible. -

$23.11 - $171.80

$23.11 - $171.80 -

$54.52 - $248.11Water-based products may experience shipping delays during cold weather months! If freezing temps are forecast, we will hold your order until safe to ship. We monitor forecast conditions everyday and will ship your order as soon as safely possible.

$54.52 - $248.11Water-based products may experience shipping delays during cold weather months! If freezing temps are forecast, we will hold your order until safe to ship. We monitor forecast conditions everyday and will ship your order as soon as safely possible. -

$23.27 - $71.87Water-based products may experience shipping delays during cold weather months! If freezing temps are forecast, we will hold your order until safe to ship. We monitor forecast conditions everyday and will ship your order as soon as safely possible.

$23.27 - $71.87Water-based products may experience shipping delays during cold weather months! If freezing temps are forecast, we will hold your order until safe to ship. We monitor forecast conditions everyday and will ship your order as soon as safely possible. -

Surfkoat

Antique Liquid Stamp Release

$32.87 - $119.95 -

Surfkoat

Surface Aid

$33.46 - $193.81Due to flammability this product must ship with a special DOT classification and cannot be returned. -

Surfkoat

Pure Mineral Spirits

$31.43 - $112.68 -

Surfkoat

Aromatic 100

$30.26 - $107.49 -

Surfkoat

Xylene

$30.22 - $174.00Due to flammability this product must ship with a special DOT classification and cannot be returned. -

$38.62 - $173.36

$38.62 - $173.36 -

$149.37 - $183.63

$149.37 - $183.63 -

Swissmex

Swissmex Industrial Acid Sprayers

$37.03 - $116.64 -

$51.71

$51.71 -

$9.58

$9.58 -

$20.21

$20.21 -

$15.95

$15.95 -

Rollers & Brushes

4" Horsehair Clean-Up Brush

$11.05 -

Other

5 Gallon Pail Strainer

$5.78 -

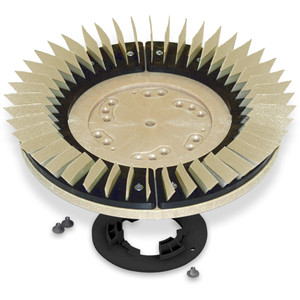

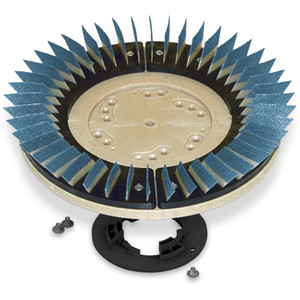

$135.50 - $459.00Malish brushes are custom built to order and cannot be returned.

$135.50 - $459.00Malish brushes are custom built to order and cannot be returned. -

$135.50 - $459.00Malish brushes are custom built to order and cannot be returned.

$135.50 - $459.00Malish brushes are custom built to order and cannot be returned. -

$135.50 - $459.00Malish brushes are custom built to order and cannot be returned.

$135.50 - $459.00Malish brushes are custom built to order and cannot be returned. -

$13.53 - $86.56

$13.53 - $86.56 -

Midwest Rake

Premium Aluminum Spiked Roller Frame

$42.77 -

Midwest Rake

Spiked Roller

$79.34 -

Midwest Rake

Speed Squeegees

$26.47 - $99.00 -

Other

Paver Wet Sanding Nozzle

$21.00 - $26.00 -

$5.95 - $67.83

$5.95 - $67.83 -

$12.10 - $137.94

$12.10 - $137.94 -

Rollers & Brushes

HD 18" Adjustable Roller Frame

$27.78 -

Rollers & Brushes

22" Plastic Paint & Sealer Tray

$16.25 -

Pro Roller

Roller Cover Endcaps

$1.72Sold per Pair -

Rollers & Brushes

9" Mo-Tech Lint Free Roller Covers - (1/4" nap)

$5.80 -

Rollers & Brushes

9" Heavy Duty Roller Covers - (1/4", 3/8", 1/2" or 3/4" nap)

$3.20 - $45.94 -

Rollers & Brushes

4" Heavy Duty Roller Covers - (3/8" nap)

$1.83 - $20.86 -

$7.88 - $119.70

$7.88 - $119.70 -

Diamabrush

Diamabrush Replacement Prep Plus Blade Kit

$128.64 - $843.24 -

Diamabrush

Diamabrush 100 Grit Concrete Prep Plus Tool

$638.58 - $1,075.17Diamabrush tools are custom built to order and cannot be returned. -

Diamabrush

Diamabrush 25 Grit Concrete Prep Plus Tool

$638.58 - $1,075.17Diamabrush tools are custom built to order and cannot be returned. -

Diamabrush

Diamabrush Replacement Removal Blade Kit

$195.84 - $391.64 -

Diamabrush

Diamabrush Removal Tool

$354.69 - $622.09Diamabrush tools are custom built to order and cannot be returned. -

Diamabrush

Diamabrush Replacement Polymer Blade Kit

$142.36 - $769.17 -

Diamabrush

Diamabrush 2000 grit Concrete Polishing Tool

$873.67 - $980.49Diamabrush tools are custom built to order and cannot be returned. -

Diamabrush

Diamabrush 1000 grit Concrete Polishing Tool

$846.11 - $949.52Diamabrush tools are custom built to order and cannot be returned. -

Diamabrush

Diamabrush 400 grit Concrete Polishing Tool

$626.35 - $722.14Diamabrush tools are custom built to order and cannot be returned. -

Diamabrush

Diamabrush 200 grit Concrete Polishing Tool

$626.35 - $722.14Diamabrush tools are custom built to order and cannot be returned. -

Diamabrush

Diamabrush 100 grit Concrete Polishing Tool

$626.35 - $722.14Diamabrush tools are custom built to order and cannot be returned. -

Diamabrush

Diamabrush 50 grit Concrete Polishing Tool

$648.19 - $743.98Diamabrush tools are custom built to order and cannot be returned. -

Diamabrush

Diamabrush Replacement Prep Tool Blade Kit

$255.42 - $454.05 -

Diamabrush

Diamabrush 100 grit Concrete Prep Tool

$402.03 - $694.56Diamabrush tools are custom built to order and cannot be returned. -

Diamabrush

Diamabrush 25 grit Concrete Prep Tool

$402.03 - $694.56Diamabrush tools are custom built to order and cannot be returned. -

Rollers & Brushes

18" Professional Deck Stain Brush

$41.28 -

Rollers & Brushes

Professional 18" Applicator Brush

$25.68 -

Rollers & Brushes

Professional 10" Applicator Brush

$15.73 -

Rollers & Brushes

Professional 4" Round Applicator Brush

$15.21 -

Rollers & Brushes

2" Chip Brush

$0.78 - $17.79 -

Rollers & Brushes

4" Double Thick Paint & Stain Brush

$3.15 - $71.82 -

Rollers & Brushes

1" Chip Brush

$0.53 - $12.09 -

Rollers & Brushes

22" Microfiber Mop Refill

$6.18